Specialists in blow moulding

At Blowtech, we’re specialists within technical blow-moulding. Blow-moulding is a plastic-manufacturing technology with high demands on precision, knowledge, and experience. You’ll find all of these at Blowtech. We can manufacture almost anything, as long as it’s made of plastic and has a cavity.

With the help of our experience, our high level of technical knowledge, and our solution-oriented approach, we’ll help you with long-term and sustainable solutions. With new technology and the right materials, we create value and help you to reduce your global footprint.

When blow-moulding is used

Blow-moulding is used to create hollow products, so-called hollow bodies. Complex shapes are often expensive to manufacture in other materials such as metal. When it’s possible to replace it with mouldable plastic, you save on space as well as weight and money.

Blow-moulding also has a lot of advantages in the manufacture of large production batches. The manufacturing goes quickly and the result is exactly the same every time. For example, blow-moulding is optimal for the production of parts for the automotive industry where this is in high demand.

In the manufacturing of complex moulds from polymer products, blow-moulding really comes into its own. Examples of this type of product could be:

• Petrol tanks

• Air ducts

• Different types of containers and vessels

• Toys

• Household products

• Products for healthcare

• Complex pipes

Usually, if you want a plastic product with a hollow body, blow-moulding is the first choice as an industrial solution.

Advantages of technical blow-moulding

• Cost-effective

• Can handle complex moulds

• Strong construction without seams

• Quick production rate

• Suitable for large production volumes

• Appropriate for use in products that demand a high degree of cleanliness, for example, foods, cosmetics, and medical technology.

The process

The raw material

The raw material, or plastic granulate, is available in different qualities with different properties, and named PP, PE.... etc. For every customer-unique product, the material is carefully selected according to requirements and specifications.

A lot of the materials are also approved for contact with comestibles. The granulate is loaded into a container on top of the machine where a large screw then pushes the material inside a hot tube so that it melts into a viscous mass. At this stage you can add important components such as colours or UV protection. At the end of the pipe is the accumulator head.

Extrusion

The accumulator head has an opening at the bottom where the material is extruded into the shape of a hollow tube, what’s known as a ‘sock’. The thickness of the sock is controlled by the accumulator head and programmed into the machine which regulates the shell thickness on the different sections of the part, based on requirements.

When the sock has become as long as the mould, the two halves of the mould enclose the sock in a cavity. The ends are compressed and the sock is inflated with air pressure, which means that the material is pressed against the walls of the mould so that the product assumes the desired shape. The hot plastic mass cools and hardens in the mould before it’s opened and the finished product can be taken out. Sometimes a certain amount of post-processing is needed on the product, and surplus material is removed. The residual material is ground down and reused directly in the manufacturing process.

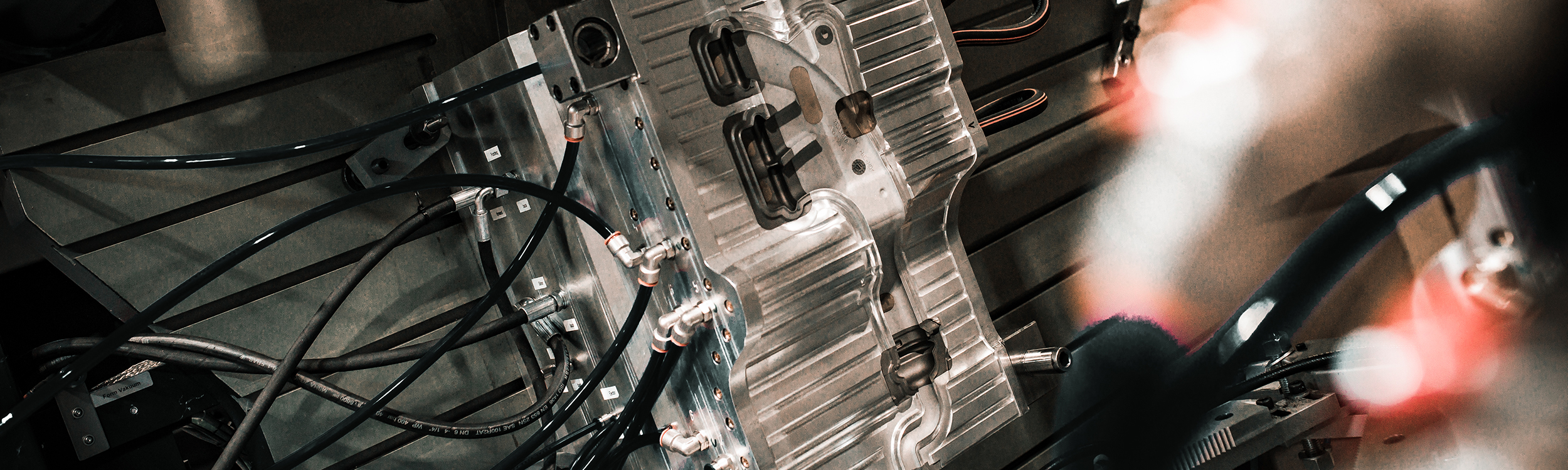

The tool

The moulds, which are specific to each project, are usually made of aluminium. Aluminium has good thermal conductivity, low weight and is easy to process. The initial tool cost is quickly offset both through high production capacity and a very long service life.

-

-

-

Teufik MehmedovicKey Account Manager Automotive